Energy Modeling

Energy modeling informs the design process, saving time and money by supporting early decision making. This service is used to rapidly identify the most effective energy efficiency and renewable energy strategies to employ in schematic design, as well as to document all of the actual strategies implemented in the final design. Energy modeling or building energy analysis is a tool for designers to “test drive” the energy performance of their building designs. It is also an analytical tool, which clearly identifies and prioritizes alternatives to optimize the design and to generate the highest savings within the budget and schedule of the project.

CDL uses the latest versions of eQUEST or OpenStudio, which are the most powerful energy modeling software provided by the U.S. Department of Energy (DOE) and provides a comprehensive hourly whole building energy simulation consistent with IECC, ASHRAE 90.1 or other reference codes. This process is consistent with industry approving modeling and building performance analysis standard. We will first provide an initial base model, and then work with the design team to develop and calculate the alternative Energy Conservation Measures (ECMs). For LEED projects, this process will lead to the recommendations for ECMs to satisfy the LEED Rating System. Finally, we will prepare related EA forms and other necessary documents for the Green Building Certification Institute (GBCI) or other jurisdictions. CDL will provide energy-modeling services broken out by the anticipated design phases.

Conceptual Design and/or Integrative Process

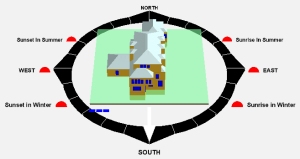

If applicable to the project or if the project is seeking LEED v4 and pursuing IP credit, during the conceptual design phase or at the beginning of the project CDL provides early analysis of energy and water systems in order to identify synergies within the project design that can optimize energy and water performances. We will quickly assemble a “simple box” energy model of the building that can be used to test the effects of site location, building layout, building massing, building orientation, and to perform a preliminary water budget analysis. While this process can quickly yield a model that may not be terribly accurate, but is perfectly adequate for comparing alternate scenarios – as relative differences are more important than deadly accuracy.

Schematic Design

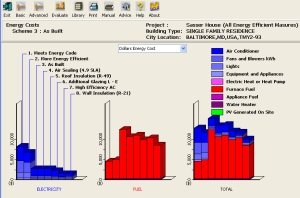

During schematic design, CDL will develop an energy model of the facility based on the schematic design drawings. Output of this energy analysis allows the design team to optimize their focus on the most promising energy-saving strategies. Seeing how the energy consumption of the project breaks down by the following categories:

- fuel type

- task

- building component

- cooling loads

- heating loads for the building

Allows the design team to focus on the major drivers of energy use. Derived strategies to examine may include:

- a different building orientation

- daylighting

- more efficient lighting

- more efficient HVAC systems

- more appropriate lighting levels

- better lighting controls

- glazing with a lower U-factor and/or lower solar heat gain coefficient

- shading for glazing

Design Development

CDL will develop an energy model of the facility given the status of the design development drawings. We will evaluate and document the building’s envelope property selection, HVAC system selection, lighting system, and develop Energy Conservation Measures (ECMs) to illustrate the energy performance impact that would improve the status of the project. CDL will work with the design team to refine assumptions as necessary, simulate and re simulate the proposed design model, evaluate the results and select the most suitable ECMs to be applied for LEED credits. A full report will be submitted at this stage, showing findings and savings after comparing the energy consumption of the baseline model and the proposed model. This report will includes CDL recommendations regarding necessary revisions to the proposed design (if any) in order to satisfy the LEED requirements. CDL assumes the possibility of applying minor changes to the project in order to meet the desired percentage of energy conservation for awarded EA points.

Construction Documents

CDL will revise the initial model and develop a comprehensive energy model of the facility given the status of the final construction documentation, narratives, drawings, and design team correspondence. We will work with the design team to refine assumptions as necessary to formulate a complete and accurate energy simulation of the facility. CDL will evaluate and document the HVAC system selection, lighting system, controls, pumps, site lighting, service hot water, process loading, and other end-uses as required per LEED and ASHRAE 90.1 modeling protocol. We will also develop a detailed or ASHRAE 90.1 Appendix G baseline energy model.

At this time, the project team will have the “Pre LEED Submission” expectation for LEED Energy & Atmosphere Credit 1 performance; barring any further changes, this will be the result that carries through to the final LEED Design Application submission to the Green Building Certification Institute (GBCI).

LEED Submittal and GBCI Review

Once the final model is approved and the design team is ready to submit the design application for LEED certification CDL will prepare the related EA Credit forms and submittals documents and will upload them to LEED-Online. Upon submission of LEED the EA Credits, the GBCI will likely respond with clarifying questions. CDL will be responsible for answering any questions within the time allocated for review.

Climatic Design = Energy Savings + Protecting the Environment

Call CDL to meet your energy savings